As a professional peristaltic pump manufacturer, LEFOO group retains a pump production base and a pump research center that can control the high production quality and R&D ability which can excellently archive customers' requirements.

The DC 12/24V Peristaltic Chemical Dosing Pump is easy to change pump head to reduce Cost & increase productivity! The Ideal Solution for pumping and dosing various types of liquids of different viscosity and temperature, acid, alkali, and sterile fluids, chemical aggressive fluids. Also, our lab peristaltic pumps can help control flow rates precisely.

Features

*Easy upkeep low noise

*Optional Brushless/Stepper Motor

*Simple setting and Easy Mounting

*Optional various soft tubes

*No pollution and Easy Maintenance

*High temperature/Chemical resistant

*Can transfer liquid, gas, solid

Pump

| LEFOO DC Motor Peristaltic Pump LFP303/DB | |

| Installations method | Build-in mounting hole (customization mounting plate) |

| Drive mode | DC brush gear motor |

| Control method | Power-on operation |

| Function | Constant speed quantitative supply |

| Working Voltage | DC12V, DC24V |

| Power | ≤8W |

| Weight | 170g |

| Working environment | Temperature: 0-45℃ Relative humidity: <85%RH |

| Roller Quantity | Standard 2 rollers+2 training wheels (4 rollers are available) |

| Voltage | Flow | Tube size | Tube material |

| DC 12V / DC 24V | 35-80 | 16# | BPT Tube / Silicone Tube/A60-F / Viton Tube |

| 70-190 | 25# | ||

| 100-280 | 17# |

| 1. Peristaltic Pump LFP303/DB | Optional Tube fitting types | |||

|  | |||

T1 16# ID3.1m OD6.3mm | T2 17# ID6.3mm OD9.6mm | T3 25# ID4.8mm OD8mm | ||

| A specification of LEFOO peristaltic pumps can be determined by many combination of parts. | ||||||

| Please select each part according to your requirement. | ||||||

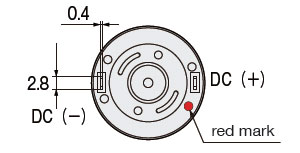

| 2. Product Series Name | Number of Rollers | DC Motor Diagram | ||||

| LFP303 (DC geared motor) | 2 roller | 4 roller | Wiring & Terminal Dimension | |||

|  | |||||

| 3. Soft Tube / Hose Select Table | ||

| (A) PHARMED BPT | Description | Regulatory compliance |

| *Great resistance to general chemicals, acid, alkali, and oxidizing agents *Compatible with virtually all commercial cleaners and sanitizers *Lasts up to 30 times longer than silicone tubes. | USP Class VI |

| (B) TYGON A-60-F (Norprene A-60-F) | ||

| For critical processing applications in the food, dairy, and cosmetic industries. *Compatible with virtually all commercial cleaners and sanitizers *Great resistance to general chemicals, acid, alkali and oxidizing agents | FDA 21 CFR Part 177.2600 NSF 51 3-A |

| (C) TYGON 3355/3350 | ||

| *High-performance and platinum-cured silicone tube *Ultra-smooth inner bore reduces the potential for particle entrapment *Excellent fluid flow characteristics. | FDA 21 CFR Part 177.2600 USP Class VI S 3-A (3350 only) |

| (D)TYGON-2001 | ||

| *Plasticizer-free chemical resistant tube. *Great resistance to a wide range of fluids that typically destroy PVC products *Applicable to soap and detergent dispensing, ink transfer, water purification lines, food, beverage and chemical transfer | FDA 21 CFR Part 177.2600 |

| (E)TYGONS3 E-LFL (TYGON E-LFL) | ||

| *Non-DEGO tube for Food & Beverage, and Biopharmaceutical Applications *Longest flex life in any clear Tygon tubes *Extremely low particle spallation for sensitive fluid applications | FDA 21 CFR Part 177.2600 USP Class VI NSF-51 |

| (F)TYGOPRENE XL-60 | ||

| *Alternative to silicones and PVC when longer pump tube life is required *Excellent resistance to a wide range of fluids, including acids and bases *Greatly reduce the risk of fluid contamination | FDA 21 CFR Part 177.2600 NSF 51 |

| (G)TYGON A-60-G (Norprene A-60-G) | ||

| *Lasts and perform better than EPDM and other specialty rubber tubes *Ozone and UV Light resistant *Applicable to soap and disinfectant dispensing, printing ink transfer. etc | |

| (H)Versilon F-5500-A(Fluran F-5500-A) | ||

| *A proprietary fluoroelastomer tube *Excellent resistance to corrosive chemicals, oils, fuels and solvents *Ozone and UV Light resistant | |

| (I)W TUBE | ||

| *Dual-wall tube which has excellent resistance to chemicals, acid, alkali. *Inner layer: Polyolefin Outer layer: Thermoplastic Elastomers | |

| 4. Color variation (The colors are software colors and not the real color) | |||||

| Blue | Green | Clear | Red | Yellow | Black |

| |||||

Recommended installation height | 2.0m max |

Liquid temperature range | 5 to 50℃(41°F to 122°F) |

Specified environment temperature range | 0 to 50℃(32°F to 122°F) |

Specified ambient humidity range | 20% to 80%(with no condensation) |

Certification & Approvals |  |

A range of tube materials is available to handle a range of different chemicals as well as hygienic options for food and beverage dispensing.

Food Machinery

Drink dispenser

Detergent supply

Dish-Washing machine,

Washing machine Analytical Equipment

Analytical &testing instrument sample supply

Printing Equipment: Ink Supply

Kitchen Apparatus

Laundry Apparatus

Car Washing Equipment Analytical Apparatus

Drink machine

Drinks dispensing

Beverage Dispenser

Soda beverage fountains

Beer brewing equipment

Coffee machine

Ice cream dispensing

Blood diagnostic equipment

Vegetable cultivation

Indoor growing shelves

Indoor Farming

Vertical Farming

Commercial washing machine

Medical device

Water treatment

Gas analysis

Printing machine

Aquarium

Hydroponics

Agriculture plating

Lab sampling

Dishwasher

Robot Sweeper

Swimming Pool

1. When selecting a tube, the customer should perform a verification test to verify the chemical suitability according to the usage environment and the intended application

2. Regardless of the pump tube type, the phenomenon of peeling from inside of the tube starts with small amounts

3. This Product is not designed for medical use. Do not use it for medical applications.

4. This product is not waterproof. The use in a water-filled environment requires water-proof systems or designs.

5. Numerical dates listed in this catalog reflect conditions measured over a short period of time. Their accuracy for long-term use is not assured.

6. There is a tendency for the flow rate to increase until the tube becomes acclimated, and even among the same model, different lots may have a different flow rate within the specified tolerances, Also, the rotating speed of the DC motor may fluctuate depending on the load condition and changes in the motor temperature. During the design stage, be sure to select a motor with ample capacity.

Product Inquiry

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification Systems English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  العربية

العربية