Transmitter

To accommodate many different applications, manufacturers make many different types of devices for pressure measurements. Examples of these include water pressure, air pressure, medical gas, oil pressure, temperature, gas pressure, fuel pressure, differential pressure, and vacuum pressure. Some of the uses of these devices are more obvious than others.

Pressure transducer Classified by the Substance They Measure

Water pressure transducer (naturally) monitors the pressure of any water-based system. Quite commonly, they are found attached to tanks, where they monitor the pressure of the water within.

Gas pressure transmitter measures and displays gas pressure. They are especially prevalent in factories and manufacturing facilities, where they keep track of the flow rate of both high and low-pressure natural gas and propane-based systems in pressure transmitter manufacturer. Fuel pressure gauges also check gas pressure levels, but they do so in the context of automobiles. They measure and display the fuel supply, or amount of gas, left in a vehicle tank.

Air pressure sensors measure pneumatic pressure in air-operated equipment.

Oil pressure transducers measure the pressure of oil circulating in a lubricating system.

Transmitter Classified by Certain Conditions They Are Designed For

Vacuum pressure gauges measure and display the pressure within vessels or systems that are immersed in a sub-atmospheric or vacuum environment. Vacuum environments are particularly used to create cold temperatures.

Seal gauge pressure sensors are made specifically to stop and avoid potential leaks. As such, they are designed with the addition of a diaphragm seal isolator. Most of their applications are found in the process, pharmaceutical, chemical, petrochemical, and sanitation industries.

Some pressure transmitters may be designed to specifically measure substances flowing at either exceptionally high velocities or exceptionally low velocities. High-pressure gauges are important to manufacturing and industrial applications for Lefoo, China leading pressure transmitter manufacturer, particularly those related to high-pressure hydraulic technology (e.g. hydro demolition, hydro blasting pumps, and water cutting machines). Low-pressure gauges are extremely accurate and sensitive, generally measuring pressures between ten and fifteen PSI. They are especially important to applications that take place in environments with frequent pressure fluctuation.

Classification by Different Standards of Pressure

Thus far, only pressure transmitters that operate with reference to gauge pressure have been discussed. A pressure transmitter that measures gauge pressure uses the surrounding atmospheric pressure as the standard by which it measures. However, this is not the only way for a pressure transmitter to operate. The main exceptions follow below.

Pressure Transmitter Classified by Types of Applications

Yet another way to approach gauge classification is focusing on the specific application a gauge is used for. To provide just one example, Pressure transmitters are a special type of pressure test gauge within the HVAC industry. Many pressure devices are designed for use with a specific type of product.

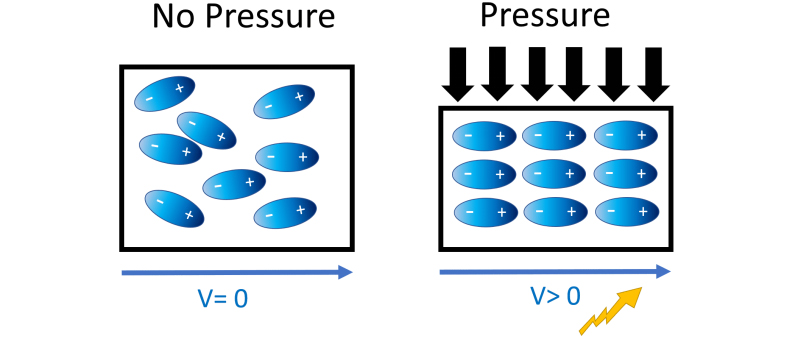

The most widely used pressure sensors in modern manufacturing industries are piezoresistive pressure sensors. And the most expensive unit in the sensor is the piezoresistive diaphragm – mostly made of Silicon Crystals and Certain Ceramics. Piezoelectric crystals generate an electric charge when exposed to mechanical stress, which is proportional to the force/pressure applied. A signal conditioner converts the charge signal into a voltage signal. Ceramics are used to measure the pressure of strong corrosive gas or liquid.

Piezoresistive pressure sensors are ideal to measure dynamic pressures. Small pressure pulsations (Such as Compressors Aerodynamic) and quasi-static pressures, Piezoresistive pressure sensors are available to measure in a short time in very high or low temperatures.

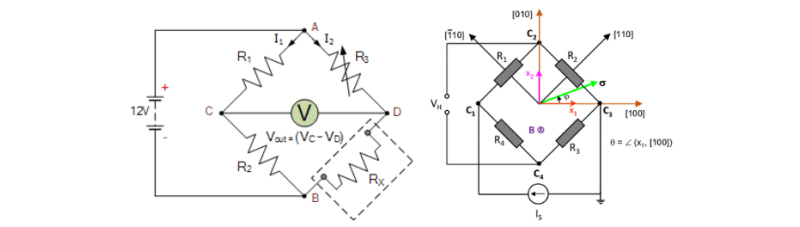

Pressure signals generated from the strain foil are too weak and need a Wheatstone bridge to amplify and optimize the measuring data. The strain type foil is the lowest cost material in many manufacturing industries. The Wheatstone bridge has 4 lines and each of them has a result and all results will be calculated to precise the measuring data.

Strain pressure measurement not available for high pressures happens in high frequency in a short time. And the measurement data are easily affected by temperature. Thus Strain sensors are not good options for modern industries such as airplanes, ships, cars, and mining industries...

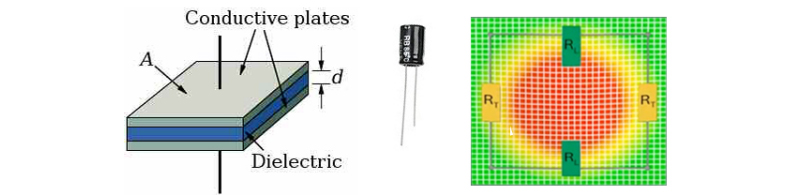

Capacitive pressure sensors use a pressure cavity and foil (diaphragm) to produce a variable capacitor. The foil has a shape transform when pressure is applied and capacitance decreases accordingly. The capacitor is a sort of battery that supplies electrical power according to pressure values. Thus this change in capacity can be measured electrically and transmit into signals. These sensors are limited to low pressures. Capacitive pressure sensors are economic in price but with higher electricity consumption than Piezoresistive pressure sensors. Capacitive pressure sensors are used in bed monitoring systems, intelligent sneakers, Door pressure switches.

Absolute pressure is the sum of gauge pressure and ambient atmosphere pressure, It measures the input pressure from a medium with reference to a vacuum zero pressure. Absolute pressure is the real pressure in closed systems or sealed containers in the atmosphere at a certain altitude. Absolute pressure is the main reference of food and beverage industries, Material industries, Transportation industries. Absolute pressure sensors are typically used in research and scientific applications.

Differential pressure measurement is based on two independent but relatively existing pressures. Pressure transducers with a diaphragm which one side measures to medium one and the other side measure another medium. The pressures are referred as to high pressure and low pressure. The application of Differential pressure transducers are very vast. Such as water processing industries, sewage treatment, fluid boilers, HVAC applications

Gauge pressure is the pressure between absolute pressure (total pressure) and atmospheric pressure. (Gauge pressure= absolute pressure- atmospheric pressure), The gauge pressure measurement is used on a car tire, natural gas transportation, hydrogen cylinder, fire extinguisher-related products. Also used in livestock feeding applications.

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification Systems English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  العربية

العربية