LEFOO LFT2010 high-precision pressure transmitter adopts a high-precision oil-filled diffusion silicon core, and is automatically tested by a computer, and the zero point and temperature performance compensation in a wide temperature range is carried out by a laser resistance trimmer. This electronic transmitter has high precision, high quality, small size and easy installation. Using a low-power high-performance MCU, the pressure signal is collected and converted into a standard analog signal output. The pressure sensor is widely used in the high accuracy pressure transducers measurement of fluid medium pressure in high-precision test systems such as fire protection, water treatment, water supply systems, air compressors, pneumatic devices, and factory automation.

Features

* Adopt oil-filled diffusion silicon core with high precision and high overload capacity

* Using special temperature compensation technology

* Excellent corrosion and wear resistance

* Product accuracy can reach 0.1%

Transmitter

| LEFOO High Accuracy Pressure Transducer LFT2010 | ||||

| Measurement Range | 0~0.1~4MPa | |||

| Overload pressure | 1.5 times of full scales | |||

| Accuracy | ±0.1%F.S. | |||

| Stability | <0.1%F.S./Year | |||

| Working temp. | -20~+85℃ | |||

| Storage Temperature | -40~100℃ | |||

| Medium Compatibility | All corrosive mediums can be compatible with 304/316 stainless steel, Fluoroelastomer or NBR. | |||

| Output Mode | Two-wired | Three-wired | Four-wired | |

| Output Signal | 4~20mA | 0~5V | 0~10V | RS485 |

| Power Supply | 10-36VDC | 10-36VDC | 14-36VDC | 10-30VDC |

| Electrical Connection | DIN43650A (Big Hirschmann), M12 waterproof outlet, GX12 aviation connector(three cores/four cores), M12 four-core aviation connector | |||

| Protection Class | IP65、IP67 | |||

| Pressure connection | G1/4、NPT1/4、R1/4、G1/2、7/16-20UNF、M20*1.5 、M10*1、M14*1.5etc. | |||

| Pressure Form | Gauge pressure G | |||

| Certification | Safety explosion-proof type E, RoHS, EU electrical safety standards CE | |||

| Code and description | Remark | ||||||||||

LFT2010 | High Accuracy Pressure Sensor | Model | |||||||||

Range | 0~0.1~4MPa | Measurement Range | |||||||||

A4 | A4 = 4~20mA(Two-wired) | Output Mode | |||||||||

| V0 | V0 = 0~5V(Three-wired) | ||||||||||

V10 | V10 = 0~10V(Three-wired) | ||||||||||

| RS | RS=RS485(Four-wired) | ||||||||||

K | K = kpa | Unit | |||||||||

| P | P = psi | ||||||||||

| B | B = bar | ||||||||||

M | M = Mpa | ||||||||||

0.1 | 0.1 = 0.1%F.S. | Accuracy | |||||||||

D1 | D1 = DIN43650A Big Hirschmann | Electrical connection | |||||||||

M | M = M12 Waterproof outlet | ||||||||||

| C3 | C3=GX12 three cores aviation connector | ||||||||||

| C4 | C4=GX12 four cores aviation connector | ||||||||||

H | H = M12 four cores aviation connector | ||||||||||

G | G = G1/4 | Pressure connection | |||||||||

| G2 | G2 = G1/2 | ||||||||||

N | N = NPT1/4 | ||||||||||

| M20 | M20 = M20*1.5 | ||||||||||

| M10 | M10 = M10*1 | ||||||||||

| M12 | M12 = M12*1 | ||||||||||

R | R = R1/4 | ||||||||||

U | U = 7/16-20UNF External thread | ||||||||||

1.0 | 1.0 = 1m | Cable length | |||||||||

2.0 | 2.0 = 2m | ||||||||||

3.0 | 3.0 = 3m | ||||||||||

LFT2010 | 0-30 | A4 | B | 0.1 | D1 | G | 1.0 | Example of Select | |||

Adopt oil-filled diffusion silicon core with high precision and high overload capacity

Using special temperature compensation technology

Excellent corrosion and wear resistance

Product accuracy can reach 0.1%

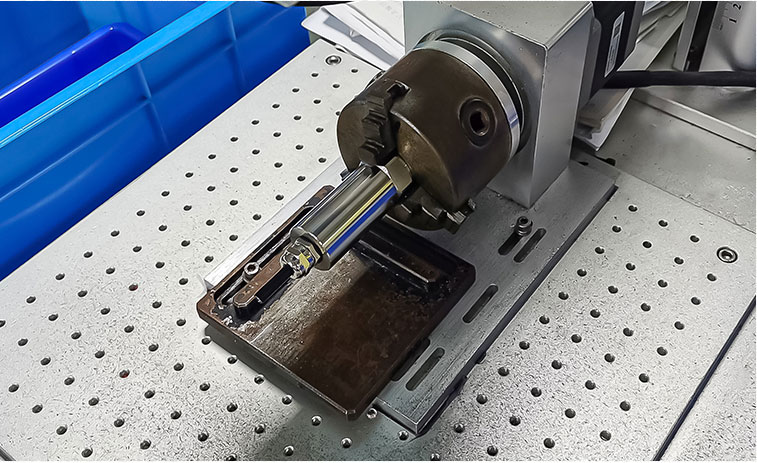

| A pressure transmitter starts with sensor selection, and LEFOO provides you with high-quality pressure transmitters through multiple checks |

|

| The calibration instruments are connected with computer, multiple calibrating undergoes to ensure the accuracy |

|

| Standard aging test rooms for pressure sensing product |

|

| Lazar Logo Machine capable of OEM logo |

|

Pressure measuring of water, oil, fluid, and gas require relatively exact monitoring value and repeatable measurements.

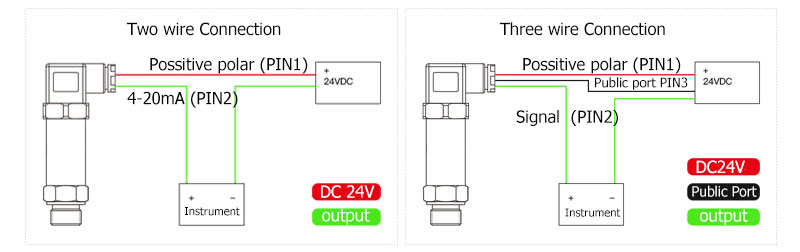

| Wire Connection Chart |

|

| Match various data collection terminal equipment |

|

Gas alarm

Injection pump

Vacuum pump

Smart water valve

Building automation

Automation equipment

Firefighting equipment

Fire extinguishing gas tank

Power energy equipment

Heating tube manufacturer

Medical supporting equipment

Ammonia detection equipment

Airtightness testing equipment

Ozone detection equipment

Chemistry experiment equipment

Urban drainage system monitoring

Hydraulic oil pressure detection

Low-speed unmanned vehicle brake control

Water processing

Watertank pressure measuring

New energy technology and equipment manufacturing

Product Inquiry

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification Systems English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  العربية

العربية