LEFOO LFT2000 water pressure transmitter is widely used in the measurement of fluid medium pressure in test systems such as fire protection, water treatment, water supply systems, air compressors, pneumatic devices, and factory automation. The ceramic sensitive diaphragm with high overload capacity has excellent anti-corrosion and anti-wear performance. This ceramic pressure transducer type of air pressure transducer adopts AS1C technology, MEMS technology, and digital compensation. It has the characteristics of small size and low price and can be used in various complex environments.

Features

* Ceramic sensitive diaphragm with high overload capacity

* Excellent corrosion and wear resistance

* Using ASIC technology, digital compensation

* Small size, can be used in various complex environments

* With a variety of threaded ports and electrical connections

Transmitter

| LEFOO Ceramic Pressure Transmitter LFT2000 | ||||

| Measurement Range | -100kPa-0.3MPa...6MPa, 0-0.3MPa...60MPa | |||

| Overload pressure | 1.5 times of full scales(Max.80Mpa) | |||

| Burst Pressure | 2 times of full scales(Max.90Mpa) | |||

| Accuracy | ±0.5%F.S., ±1.0%F.S. | |||

| Stability | <0.5%F.S./Year | |||

| Working temperature | -20~85℃ | |||

| Storage Temperature | -40~100℃ | |||

| Medium Compatibility | All corrosive mediums can be compatible with 1Cr18Ni9Ti, 304 stainless steel, Fluoroelastomer or NBR. | |||

| Output Mode | Two-wired | Three-wired | ||

| Output Signal | 4~20mA | 0.5~4.5V | 0~5V | 0~10V |

| Power Supply | 10-36VDC | 4.75-5.25VDC | 10-36VDC | 12-36VDC |

| Electrical Connection | Packard, DIN43650C (Small Hirschmann), DIN43650A (Big Hirschmann), M12 waterproof outlet, M12 aviation connector, GX12 aviation connector(three cores/four cores) | |||

| Protection | IP67、IP65、IP54 | |||

| Pressure connection | G1/4、NPT1/4、R1/4、BPS1/4、G1/2、7/16-20UNF、M20*1.5、M10*1、M14*1.5 etc. | |||

| Pressure Form | Gauge pressure G | |||

| Certification | RoHS, EU electrical safety standards CE | |||

| Code and description | Remarks | ||||||||||||

LFT2000 | Ceramic Pressure Transmitter | Model | |||||||||||

Range | -100kPa~0.3MPa...6MPa, 0~0.3MPa...60MPa | Measurement Range | |||||||||||

A4 | A4 = 4~20mA(Two-wired) | Output Mode | |||||||||||

V05 | V05 = 0.5~4.5V(Three-wired) | ||||||||||||

V0 | V0 = 0~5V(Three-wired) | ||||||||||||

V10 | V10 = 0~10V(Three-wired) | ||||||||||||

K | K = kPa | Unit | |||||||||||

| P | P = psi | ||||||||||||

| B | B = Bar | ||||||||||||

M | M = MPa | ||||||||||||

0.5 | 0.5 = 0.5%F.S. | Accuracy | |||||||||||

1.0 | 1.0 = 1.0%F.S. | ||||||||||||

P | P = Parkerd connector | Electrical connection | |||||||||||

D | D = DIN43650C Small Hirschmann | ||||||||||||

D1 | D1 = DIN43650A Big Hirschmann | ||||||||||||

M | M = M12 Waterproof outlet | ||||||||||||

| C3 | C3=GX12 three cores aviation connector | ||||||||||||

| C4 | C4=GX12 four cores aviation connector | ||||||||||||

H | H = M12 four cores aviation connector | ||||||||||||

G | G = G1/4 | Pressure connection | |||||||||||

N | N = NPT1/4 | ||||||||||||

| G2 | G2 = G1/2 | ||||||||||||

| M20 | M20 = M20*1.5 | ||||||||||||

| M14 | M14 = M14*1.5 | ||||||||||||

| M10 | M10 = M10*1 | ||||||||||||

| U | U = 7/16-20UNF External thread | ||||||||||||

R | R = R1/4 | ||||||||||||

B | B = BSP1/4 | Cable length | |||||||||||

1.0 | 1.0 = 1m | ||||||||||||

2.0 | 2.0 = 2m | ||||||||||||

3.0 | 3.0 = 3m | ||||||||||||

LFT2000 | 0-60MPa | A4 | B | 1.0 | P | G | 1.0 | Example of Select | |||||

Ceramic sensitive diaphragm with high overload capacity

Excellent corrosion and wear resistance

Using ASIC technology, digital compensation

Small size, can be used in various complex environments

With a variety of threaded ports and electrical connections

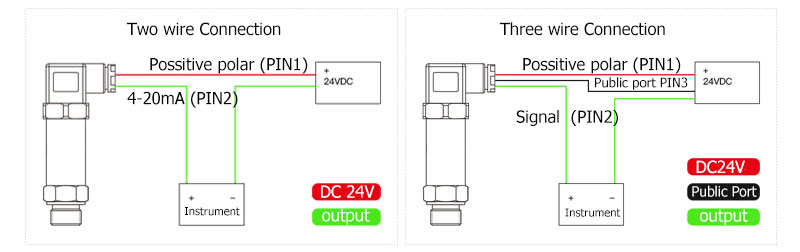

| Wire Connection Chart |

|

LEFOO pressure transducer T2000 Match various data collection terminal equipment such as Frequency Converter, Signal Isolator, pressure control device, and PLC in applications as below.

Analytical tools

Automotive pressure monitoring

Air conditioning refrigerant monitoring

Beverage industry

Chemical chemistry

Confluence Exhaust

Car Charging Pile Coolant

Extruded board, thermal insulation board for underfloor heating

Gas alarm

Gas stove and vending machine

HVAC systems

Hydraulic equipment

Hydraulic base station

Hydraulic Robot Brake Control

Heat, power generation, auxiliary equipment

Luxury bath

Lithium battery manufacturing

Marine facilities

Mining industry

Medical Gas Alarm

Ozone equipment

Oil Testing Equipment

Power Project Test

PLC systems such as medical projects, HVAC, laboratory

Refrigeration equipment

Vacuum pump

Pharmaceutical industry

Pulp and paper

Pure water cooling device

More so than other industrial devices, pressure sensors/pressure transmitters/pressure transducers, are frequently used in conjunction with complementary instruments, like pressure switches, pressure gauges, and digital pressure controllers. with the addition of these devices, pressure transmitters increase instability with no margins of error generated from industrial energy instruments by magnetic chaos. They may also be equipped with electric contacts that sound alarms, turn on signal lights, or control a valve or pump. Two specific examples of accessories used to increase the functionality of gauges are test point adapters and gauge isolators. Test point adapters fit gauges and allow them to screw onto various points within the system, enabling a wide range of test pressure measurements without the purchase of multiple, separate gauges. Gauge isolators turn a pressure gauge into an “on/off” mechanism by mounting between a gauge and its circuit; unless a button is activated, the gauge will not be exposed to and will not read fluid pressure.

Many accessories for pressure transmitters have protective purposes. As sophisticated industrial instruments, pressure transmitters face a variety of threats such as pipe vibration, water condensation, etc. The aforementioned gauge isolator also serves a safety function by protecting a pressure transmitter’s internal mechanism from sudden pressure spikes. Snubber dampers provide a similar function by damping intense fluctuations in pressure. A variety of case protectors can be purchased to protect the exterior of a gauge from hard shocks, while chemical seals are available to protect pressure transmitters from being corroded or plugged up. While pressure gauges generally do not require a high level of maintenance, investing in protective accessories is one of the best things gauge users can do to protect and extend the life of a gauge.

When choosing a pressure transmitter for a specific application, several factors should be taken into account. Some of the major considerations include the size of the dial, the size of the connection or port the gauge will be used, units of measurement that the pressure transmitter is capable of (e.g. PSI, mmHg, PA, etc.), compatibility of gauge material with the operating conditions (including temperature, corrosiveness, etc.). and whether the gauge should be dry or liquid-filled (the latter tends to have longer life due to shock absorption).

One of the most important factors to consider is the pressure range. Generally speaking, you should use a pressure transmitter that is able to read at least twice the amount of the expected working pressure. This provides a reasonable margin of safety for using the pressure transmitter. As a rule of thumb, operating pressure should never go above three-quarters of a pressure transmitter’s reading range. A corollary of the rules of thumb involving pressure is the importance of choosing application-specific pressure gauges. Hydraulic systems, for example, should only utilize hydraulic gauges designed for operating under normal conditions in hydraulic environments.

For even greater accuracy – as well as greater speed, reliability, and durability – digital pressure transmitters should be used in place of pressure gauge devices (despite their cheap expense). Keep in mind, however, that the limitations of transmitter devices can often be overcome with the variety of accessories available for pressure transmitters. (For example, some temperature transmitters possess temperature compensation equipment and multiple calibrate circuit to enhance the accuracy of their readings.)

Since so many factors constitute proper pressure transmitter selection, investing in a quality pressure transmitter provider is one of the best choices that consumers can make. You should focus on finding a reputable provider that offers a broad array of pressure sensing/ control products and/or services (e.g. recalibration services.) Working with a quality supplier will ensure that you are able to maximize the usefulness and effectiveness of your pressure transmitter for your particular application.

Product Inquiry

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification Systems English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  العربية

العربية